Post Graduate Profile, Joseph Coddington

We love it when DA friends share their work. Joseph Coddington’s postgraduate research (at Victoria) is an incredible foray into the dimensionality of an image, technological experimentation and the future of design production with additive means.

Kia ora Joseph, What is your background and how did you get into design?

Kia ora, I’m Joseph Coddington – a designer/innovator who was lucky enough to attend Victoria University of Wellington with some amazing people, both within and outside of the Design School. I found myself attracted to design due to a fundamental passion to ask and answer questions that have not been explored before. My earliest inspirations are Richard Talyor at Weta Workshop and John Britten; both of whom demonstrate an understanding of what can happen when working both hard and smart for a creative endeavour you believe in. These early inspirations would remind me later in life that a creative path would be a perfect fit, and inspire me to study Design Innovation at Victoria University.

We thoroughly enjoyed your research investigating dimension in the (re)production of imagery. (And the outcomes of your visual exploration are phenomenal). When did you first learn about the Voxel printing method and what piqued your interest?

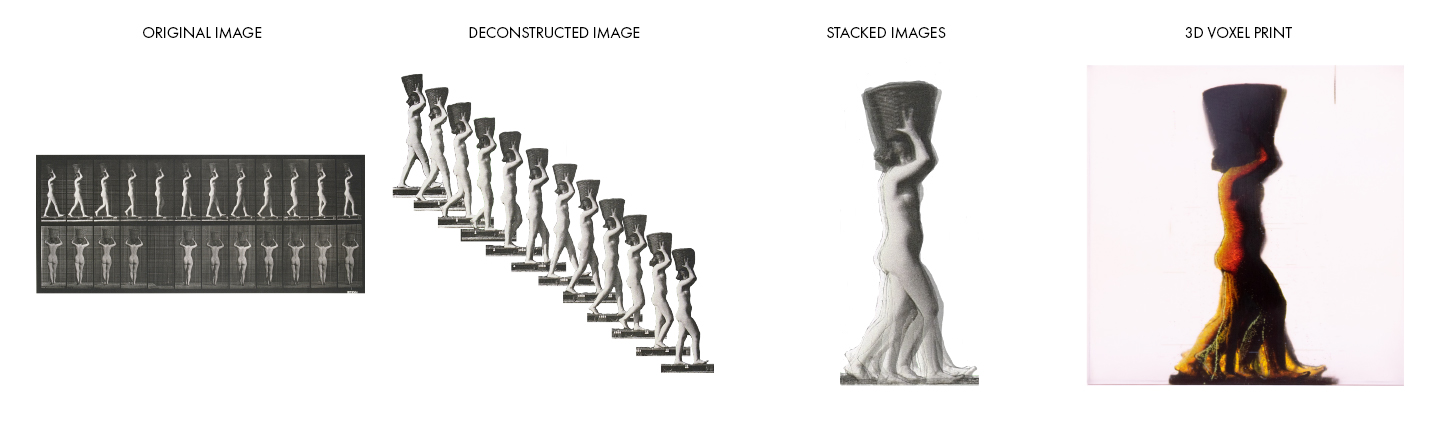

In 2018, during the final year of my undergraduate degree, a paper called Future Under Negotiation presented the opportunity to complete one print overseas on Stratsys’s J750 voxel printer. Instead of using the then-popular Houdini software, I used Adobe Photoshop as a tool for voxel printing. This is because a digital image is made from pixels, and therefore a voxel print could be designed by sequencing multiple digital images. Within three weeks, I was able to complete a cutting edge print, voxel printing film footage, which became a technological success. Due to my love of all things image-based, the image to voxel 3D print technique presented a world of potential crafted objects I had to explore.

What were the catalysts and inspirations for this Master of Design Innovation research project?

Voxel Printed Film became the catalyst for the Master’s Research. I had an internal feeling that if I applied the technique to other forms of images that were previously unexplored or mentioned, then exciting results were achievable. The inspiration comes from designing an outcome that nobody was thinking about, and was encouraged by my supervisor Ross Stevens.

I believe that every designer’s dream is to start a path of creative thought, where the consequences are yet to be realised; that in itself becomes a strong inspiration, as the outcome falls on the designer’s ability and willpower to ‘walk the path’ and design the conclusion.

Another fantastic inspiration is D.H Lawrence’s poem named: Things Men Have Made. Although the title is dated, the essence of the poem is an inspiration for designing with any technology, it reads:

“Things men have made with wakened hands, and put soft life into

are awake through years with transferred touch, and go on glowing

for long years.

And for this reason, some old things are lovely

warm still with the life of forgotten men who made them.”

My wish is that the Voxel Print of Claude Monets Water lilies will be “warm with life” like the original paintings Monets painted, which to this day provide a sense of calm to the viewing audience.

What can you tell us about the technology and working with the Stratasys J750?

It was a real privilege to work on the Stratasys J750, primarily because it was, and I believe still is, a technology in its infant stage. Therefore it provides opportunities to innovate, not just on the designed output but for the design and technical processes as well. This makes it an extraordinary tool in the hands of students or anyone creative.

The major new feature is that it offers voxel printing, where the internal structure of designs can be altered at a high resolution (.014mm squared). These alterations include changing the colour and material density of each voxel within the print, with the added feature of printing in clear material as well. Being able to design objects internal structure, changes the way we understand designed objects, and that is a credit to the J750 printer.

Your research centres on the metaphor that “if the printer can fabricate pixels, then it can fabricate images made from pixels.” However, far from mechanical, the outcomes you achieved have a soft ethereal quality. Is this atmosphere a result of the depth/multi-dimensions? What insight can you give us to the voxel process?

It’s a great question, and one I find easier to answer by designing an object than using words, but here goes:

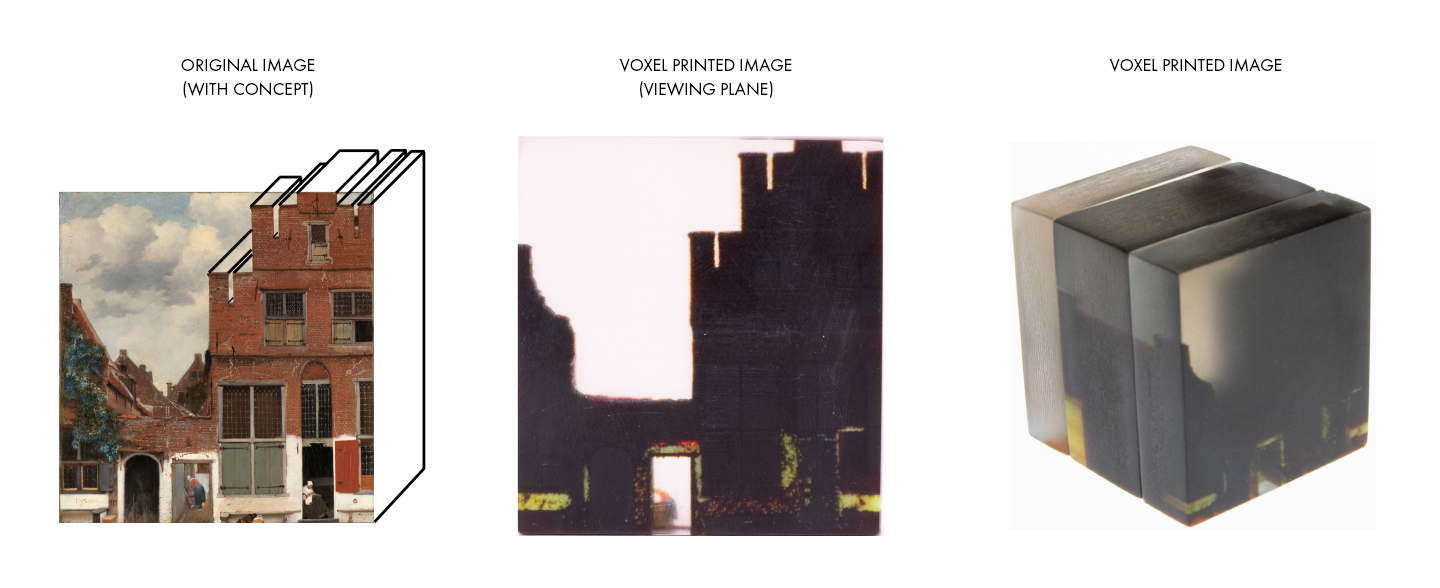

I would start by pointing out that a voxel printing trend is the use of images with objective data, such as CT scans. Objective images lend themselves well to research, as they become easy to draw scientific conclusions from. However, when using subjective images such as paintings where the image data can be far from objective, then the conclusions also become less objective.

What you gain is the added quality of depth to an image that has previously been restricted to a 2D plane. A good voxel printed image will use an image where the artist is trying to present 3D qualities on a 2D viewing plane; therefore we can take the previously restricted 3D quality and create a (subjectively) correct depth via voxel printing. As the image data is now within an object we have a tacit understanding of the original image; or as you say a multi-dimensional understanding. Unlike the 2D originals, voxel printed images are tacit objects due to the added physical depth and therefore occupy space. By occupying space, they provide a heightened sense of atmosphere; this is a massive advantage when designing in the physical realm (3D print) rather than the digital realm (online image).

Furthermore, if you are using an artist image, then where possible uplift the artist painting process to the voxel printing process. For example, Claude Monet painted “Water Lilies” layer by layer, this process lends itself well to the J750 which 3D prints voxels layer-by-layer, or image-by-image.

In short, when 3D printing, the designer’s goal should be to energise the 2D image by adding depth to it. Bad design would use an image that does not call for an added physical depth, and therefore lacks justification for 3D printing.

And how did thinking about image-making outside of the constraints of a single plane shape your understanding of the relationship between Art, Design and Craft?

I think it is safe to say that artists have a very good understanding of 3D concepts, and maybe a better understanding than academic research; they just use a 2D canvas to explore the 3D concept. So the knowledge was always there for me to draw an understanding from. From my end, it just needed a designer or someone who is not bound to a 2D format to express the knowledge through craft or design. That being said, I believe my research encapsulates the essence of a relationship between art, craft design and research; not only for using images to craft objects but incorporating artistic process and philosophy into the sphere of design and design research. The arts, craft, design and research debate has occurred for over 100 years now, and this work aims to present a solution that binds all those disciplines into one unified body of work.

Do you have a favourite voxel printed image and if so why?

I like the Claude Monet print for two main reasons. Firstly the print documents a pure transition from digital image to physical print. Not only is it physical, but the tacit quality of light projecting through the print documents the ability to craft something digitally that responds to the natural environment. I managed to achieve this without any prototypes, which lends itself to a pure design process that is common in New Zealand innovation.

Secondly, when I was five years old I painted my version of Claude Monet’s Water Lilies, so the idea of returning to Monet aged 25 excited me.

Have there been any breakthrough moments – when you found something unexpected along the way?

I think the most significant breakthrough came from watching a video of Gerhard Richter paint one of his ‘squeegee’ paintings. Richter applies a large amount of paint and smears it across the canvas, and then scraps parts of showing the physical nature of the painting. There is an obvious metaphor to Voxel printing in his layer-by-layer method, as, like Richter, the printer also prints layer-by-layer (just horizontally, not vertically like Richter). On top of the layer-by-layer similarities, Richter has always explored colour, which is a key component of the Stratasys J750 printer. Without knowing these similarities, I probably wouldn’t have come up with the idea of exploring art as image data to voxel print.

You documented some challenges both with the technology and the pandemic response interrupting your tech access. What was the most challenging part of your research and how did you overcome this?

The disadvantage when using new technology is when a technical problem happens then it can be hard to fix fast. During my research, the J750 printer was unusable for 5 months, and almost imminently being fixed New Zealand went into lockdown. I was in a unique position of having no prototypes or writing done, and no set path on how to complete my masters. I used the lockdown time to develop a new idea (voxel printing images) and decided to complete the design work without any prototypes, instead of backing my design ability to get the design done once and right. It sounds straight forward but goes against the common academic practise, where students can present 50+ prototypes that showcase and academic rigour. Instead, I would take inspiration from the fine arts, crafts, and the Bauhaus, where using your mind as a laboratory for prototyping is fast, cheap and you can vary the pace. This process is common practice at the undergraduate level, whereby students submit project after project, and there is no need (usually) to prototype, due to the constant time constraints. t is a great credit to place students under this pressure, as it develops a sense of mental design toughness, which allows them to pivot their ideas and processes should an obstacle prevent the work from taking place.

What are your goals and aspirations for the future?

I think my long-term goals are more value-based than career based at this stage in life. I always want to be in a position to use and challenge my mind, remain curious and have the energy to act on that curiosity through any creative medium. the short -term goal is getting a job, and although it’s a tough environment post covid, I’m enjoying learning what businesses are out there and spending the time developing design skills the job market is after.

What is the future of 3d printing, and what insight can you give us to how additive manufacturing may impact design practice going forward?

This is the ultimate question, where even people who are far more informed than me struggle to form an answer. What is certain is that 3D printing not only changes the way we manufacture but changes what we can create and the thought process behind the creating. It’s far more democratic in terms of what is good design, as someone with no design or craft knowledge can learn a technical skill, and quickly create an idea nobody has thought of. That’s the part that excites me, the potential for new ideas and the stories of where those ideas come from.

What other design production innovations are you excited about?

I’m spoilt for choice in answers to this question, but I would have to refer to the work completed by my classmates from design school. There is some fantastic work both at undergraduate and post-graduate levels, some of which is nothing short of world-leading. Working next to these people for five years, not only excited me but inspires me. The university usually runs an end of year exhibition, and I would defiantly recommend spending some time there and soaking up the innovations.

And, finally, How can people contact you?

I keep most of my work on hand but keep an active online profile on Linkedin, or feel free to contact me directly at: josephcoddington@hotmail.co.nz

A massive thank you to Design Assembly for the interview, and thank you reader for your time!